SCADA and IoT monitoring systems - Why invest?

16:43 - 26/06/2019

The role of SCADA system

The world is moving towards automation and intelligence. Hence, this leads to a need to understand machine control operations. In this day and age, machines have taken over the manufacturing, manufacturing and packaging operations of any industry. Therefore, the role of a SCADA monitoring and control system is indispensable.

The fact is undeniable that machines have to be manually operated and internal handling needs to be supervised. And here is what SCADA does:

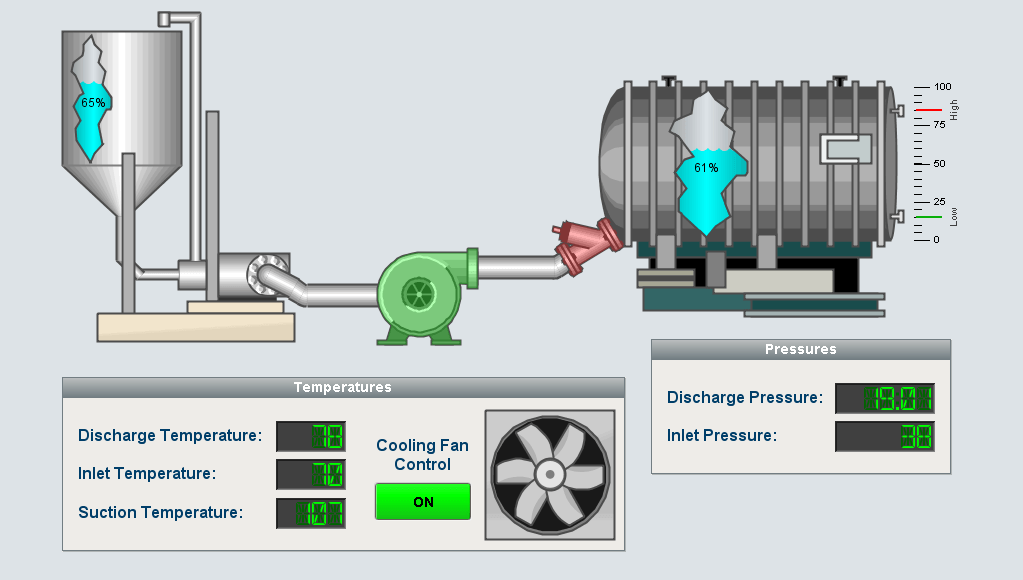

- Collect, monitor and process real-time data from connected physical devices

- Local or remote control of industrial processes

- Log events and data to a machine log file

- Interact directly with devices such as sensors, valves, pumps, motors and more via human-machine interface (HMI) software

- As a bridge between unstructured data and digital data

SCADA control functions

SCADA software is integrated with hardware or machine components to simplify a given infrastructure. However, their components are quite complex. There are five most important subsystems of the SCADA system that make it the future of industrial processes:

- Robot interface (HMI)

- Monitoring system

- Remote terminal (RTU)

- Programmable logic controller (PLC)

- Communication infrastructure

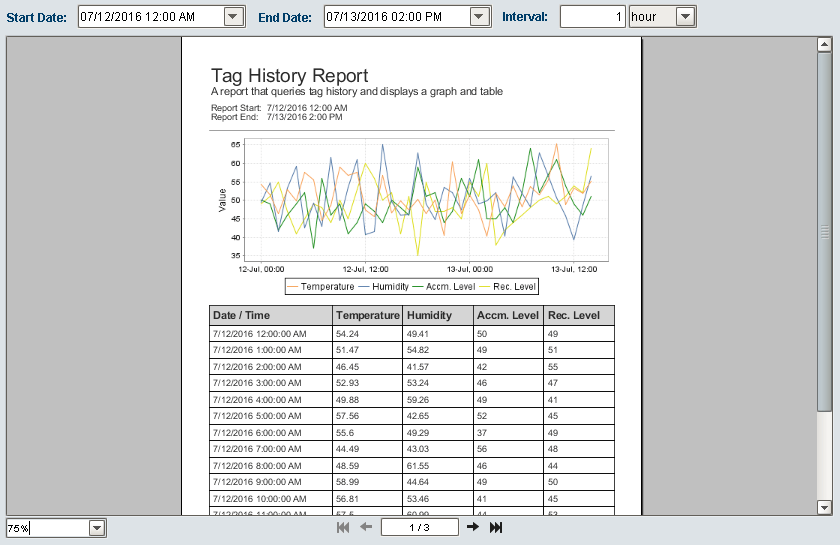

Reporting functions of SCADA

SCADA is a recent phenomenon when IoT started to emerge. The system works closely with the hardware and software components. The hardware gathers and feeds the data into the computer's processor. The computer will then process the recorded data at different intervals. SCADA also records and logs all events to a file stored on the hard disk or sends them to the printer. The software raises warnings when conditions become dangerous or tend to harm the entire system.

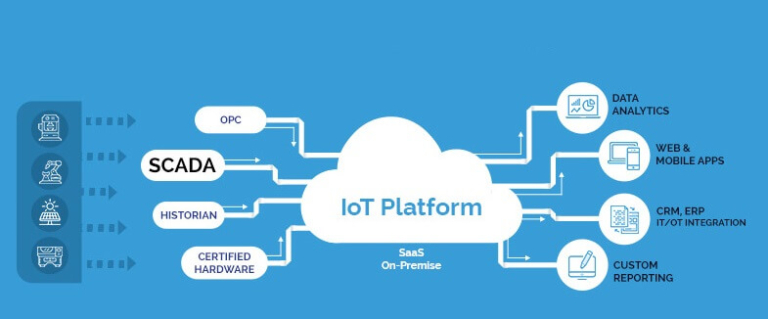

IoT vs. SCADA

Ease of installation, cost reduction, increased data accuracy, and worldwide remote control and monitoring are all the things that the IoT offers for manufacturing industries. However, since the IoT is a relatively new technology related to SCADA and PLC, its capabilities can naturally adapt to the needs of modern industry. That being said, when SCADA started, it allowed manufacturers' systems to work together in real time, just like the IoT was doing. Hence, it is very clear that the strength of SCADA systems and its technological capabilities are still relevant even in Industry 4.0. Where it lacks, however, is handling the rest of a business to create a truly connected ecosystem. The question should not be about removing or replacing SCADA, but SCADA?

Currently, the IoT is revolutionizing SCADA by offering more standardization and openness. The IoT is also providing enhanced scalability, interoperability, and security by introducing the concept of the IoT platform. Essentially, both platforms are used to increase overall productivity by integrating intelligent maintenance. As well as reducing waste, increasing efficiency, reducing downtime and extending equipment life.

Information generated from SCADA systems acts as one of the sources of data for the IoT. SCADA's focus is on supervision and control. Meanwhile, the IoT is more focused on analyzing machine data to improve productivity and impact your top product line. The IoT is essentially a culmination of the advances in the interconnectivity of the hardware and data networks that SCADA provides. As well as cloud computing and data processing bit. In short, the IoT starts when SCADA and PLC end.

So while the IoT market is still in its early stages of production, it could coexist with SCADA. The IoT is bringing a wave of new technology and business models that is changing the face of SCADA. However, the SCADA model has always been a flexible model for change in the industry.

If you already have a SCADA system, you can integrate the IoT solution with your SCADA system and collect data from a Data Collection System (DAS) machine. By leveraging the power and scalability of the IoT, you can use the collected data to generate a variety of reports such as the Overall Equipment Performance report, the Production Data report, and the other. utility reports (gas, water, electricity).

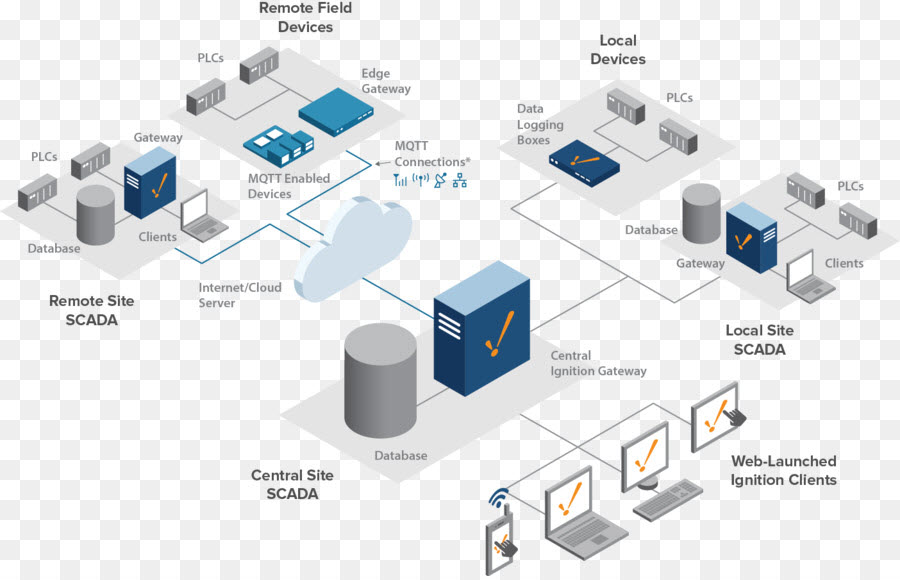

In the future, it is likely that SCADA systems will evolve into IoT systems. Devices and PLCs will become smarter and can integrate different cloud platforms. This will allow new security platforms to further secure any data recorded. This means improvements that will save money can be made.

SCADA is about allowing people to interact remotely with a process. Meanwhile, IoT is often used as a communication tool between machine and machine. Instead something exists primarily for presenting information to a human being. That's just a small part of the process. The IoT ensures that information is shared with both humans and machines, rather than just people. In short, it ensures that everyone and everything is kept connected at all times.

Integrating SCADA and IoT

Admittedly, the SCADA platform is lacking in particular innovations, otherwise the demand for IoT will be much better. SCADA is currently affected by IoT concepts and solutions that are rapidly being integrated into the SCADA architecture. This is done so seamlessly that we will never notice the difference.

Coordinate IoT and SCADA

However, SCADA is still limited to the factory area. The data taken from the factory equipment is only viewed inside the factory. Meanwhile, IoT takes that data, provides detailed information to users, and provides that data anywhere, anytime. This, in turn, allows new business models to be created thanks to its real-time and access Everywhere.

The future of SCADA and IoT

Both SCADA and IoT are involved in sensors and data collection. Although they differ in many ways, the two share the same goal. Utilization optimization and ultimately greater control over some equipment or a process. The whole concept of smart grid leads to integration of SCADA and IoT. Because SCADA is not a full control system, but instead is a computer system that collects and analyzes real-time data, which is very useful in monitoring and controlling factories or industrial equipment. . It will gather information about a risk, turn it back to a central web site and alert home station. It then performs any necessary analysis and controls and displays the information in a way that is logical and organized for human interpretation and use accordingly.

The Internet of Things is made up of a network of physical devices connected through electronic embedding, software setup, sensor actuators, and networking, all working together to make objects connect. join and exchange data. The IoT allows objects to be perceived or controlled remotely on various network infrastructures. Thus, it offers an opportunity to more directly integrate the physical world into computer-based systems. This leads to improved efficiency, accuracy and economic benefits and also cuts down on human intervention.

Both platforms offer a lot of advantages, as well as a number of flaws. It is predicted that by 2020, 50 billion devices or objects will be connected to the internet. Hence, the dynamics of an Internet-based control system is becoming a living reality. Industry 4.0 is an era in which the trend of data exchange in manufacturing technologies is allowing the transition from traditionally deployed SCADA to a deployed IoT. With SCADA, cyber physics systems, Internet of Things, cloud computing and cognitive computing, Industry 4.0 is the era that will change the dynamics of the entire automation industry.

Why need to invest in SCADA or IoT monitoring system?

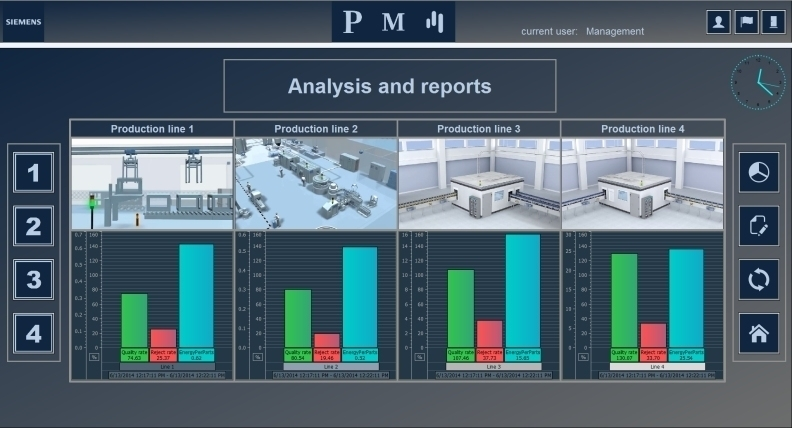

Although each market segment may be different and have different needs, overall, SCADA and IoT are ideal for data centralization and visualization for remote monitoring and control. . This will provide operational improvements through enterprise-wide visibility and standardization, which is a common way to view operational data for quality, process, and KPI consistency.

Thus the effects of investment can be seen clearly:

- Improved engineering efficiency - reducing engineering costs and the complexity required to build and maintain a system as there are a number of functional modules that automatically do complex human tasks 24/7

- Enhanced asset lifecycle management - reduce upgrade and maintenance costs because the system already has real-time alerting and data logging.

- Empower activities - increase operational efficiency from more powerful information and simplify usability

- Always have accurate information about what's going on - helping you to react quickly to changes or problems in production and business.

- Increase visibility across production network

- Improved regulatory compliance in production - factory safety and product quality because the system automatically alerts you when problems occur.

- Standardize business operations according to what is committed - SCADA IoT automatic collection and monitoring system will ensure all workflows work properly and closely follow necessary KPIs in real time.

Production KPI monitoring with SCADA WinCC OA